Are you interested in our solutions? Then write us a message. Our sales team will be happy to help you.

Start enquiryAnyone who takes environmental protection seriously cannot only hold new vehicles up as the answer – they need to offer solutions for existing vehicles, too. Internal-combustion engines powered by carbon-neutral, synthetic fuels are an important element of more eco-friendly mobility for this exact reason.

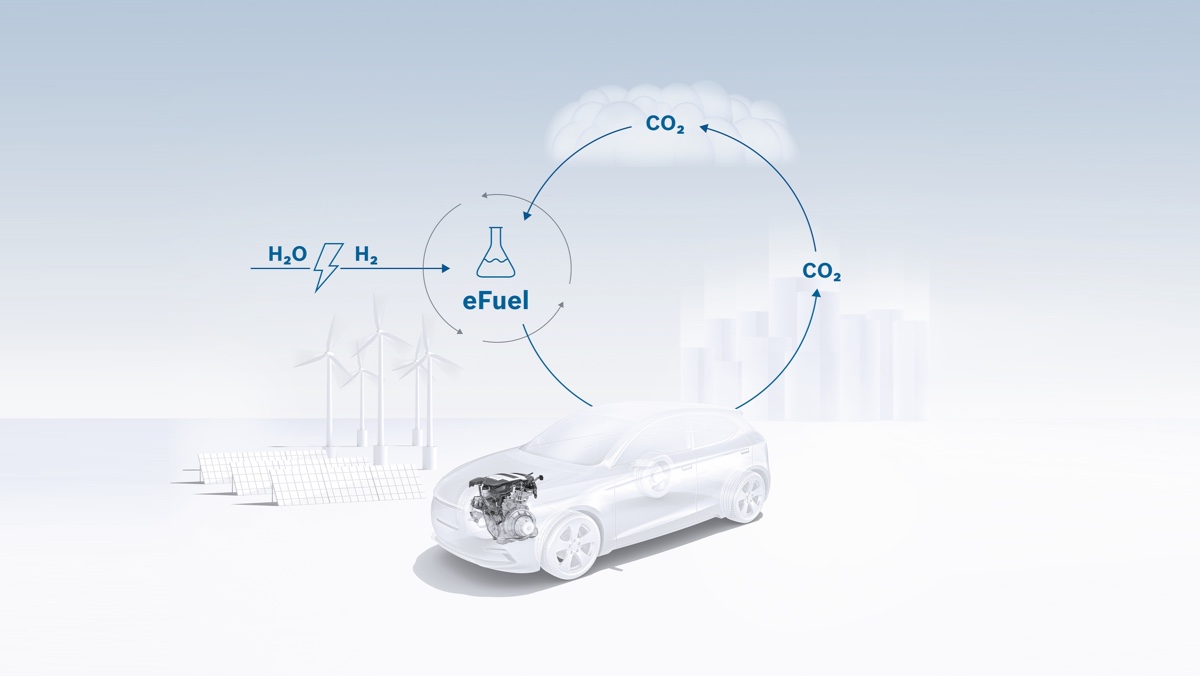

Curbing CO2 emissions is one of the biggest challenges of our times. This goal can only be achieved if we considerably reduce the use of fossil fuels in the near future. This is where renewable synthetic fuels play a key role. Synthetic fuels generated from renewable energy sources ensure carbon-neutral combustion. This is not only true for new vehicles, but also for the 1.3 billion or so vehicles that already exist.

Ansgar Christ explains in an interview why transparency about CO2 is especially important, how future climate targets can be achieved with renewable synthetic fuels, and how sustainable fuel sources will be crucial for mobility in 2030.

of all internal-combustion engines might be run on carbon-neutral fuels

existing vehicles can be filled up with renewable fuels, thereby helping to achieve environmental targets

large-scale use of synthetic fuels could save gigatons in CO2 emissions.

Synthetic fuels offer great potential when it comes to achieving emissions targets. Here, the spotlight is on so-called drop-in renewable fuels. This term means that the respective fuel mixture conforms to standards like EN228 (gasoline), EN590 (diesel), or comparable alternatives.

Today, diesel vehicles can already be filled up with R33 fuel available at the pump, helping to reduce CO2 emissions by up to 20%. In principle, the CO2 saved can be anything up to 100% depending on the mixture and production method.

Expert for synthetic and regenerative fuels at Bosch

Bosch promotes the use of biofuels produced from residual and waste materials. Their potential to minimize CO2 emissions makes biofuels an important factor for environmental protection and for satisfying legislation on the reduction of greenhouse gases. Biofuels must satisfy the EU’s sustainability criteria.

The poor availability of drop-in-capable components is one current challenge that must be overcome if biofuels are to be rolled out on a wide scale.

C.A.R.E. diesel is fuel produced from residual and waste materials. This paraffinic fuel, which is up to 100% renewable, is produced from biological waste (such as used cooking oil and grease) and contains zero conventional diesel from fossil sources.

C.A.R.E. is a trademark registered by Toolfuel and stands for the fuel’s four advantages: CO2 reduction, Arctic grade (cold resistance), Renewable, and Emission reduction.

Up to 33% of R33 Blue Diesel fuel consists of biological components, with the remaining 67% comprising diesel. Using this fuel guarantees a 20% reduction in CO2. Furthermore, the fuel is compliant with fuel standard EN 590, enabling it to be sold from public gas stations.

The biological share of this fuel is exclusively produced from waste material and by-products like used cooking oil.

Ethanol is a type of alcohol extracted from plants that is also is used as a fuel. Until now, ethanol has mainly been produced from sugar cane or starchy plants. Yet new technologies are based on using biomass from raw materials containing cellulose, such as maiden silvergrass.

In this way, ethanol notably reduces the carbon footprint and is admixed to conventional gasoline. The ethanol content varies between 5% (E5) and 85% (E85) in this case.

Are you interested in our solutions? Then write us a message. Our sales team will be happy to help you.

Start enquiry